- Menu

- Accueil

-

Produits

-

-

-

-

-

-

-

- Échangeurs de chaleur pour bières et boissons Alfa Laval®

- Échangeurs de chaleur à surface raclée CONTHERM® Alfa Laval

- Échangeurs de chaleur tubulaires Alfa Laval®

- Échangeurs de chaleur liés par fusion Alfa Nova®

- Refroidisseurs d'échantillons Steriflow

- Échangeurs de chaleur à plaques brasées Alfa Laval

- Voir plus →

-

-

-

-

-

- À PROPOS

- Contacts

- Demande de Soumission

- Boîte à outils

- Catalogs

- Télécharger le certificat MTR

Systèmes de nettoyage en place

![]() ® Systèmes CIP (Nettoyage En Place) sont conçus pour répondre à vos attentes. Nos systèmes CIP requièrent peu d'entretien et sont de qualité supérieure. Ils sont minutieusement inspectés et testés avant l'expédition.

® Systèmes CIP (Nettoyage En Place) sont conçus pour répondre à vos attentes. Nos systèmes CIP requièrent peu d'entretien et sont de qualité supérieure. Ils sont minutieusement inspectés et testés avant l'expédition.

L’équipe technique de Haleson vous aidera à choisir le système CIP (NEP) qui convient à votre application. Notre personnel est dédié, courtois et vous offre son expertise dans un esprit gagnant-gagnant.

![]() ® Systèmes CIP(NEP) sont conçus pour l'alimentation en générale, bière, vin, boissons, produits laitiers ainsi que pour les produits chimiques, pharmaceutiques, cosmétiques, aseptiques et autres applications sanitaires.

® Systèmes CIP(NEP) sont conçus pour l'alimentation en générale, bière, vin, boissons, produits laitiers ainsi que pour les produits chimiques, pharmaceutiques, cosmétiques, aseptiques et autres applications sanitaires.

Haute efficacité: Nettoyage efficace et en profondeur, augmentation du temps de disponibilité de l’usine, faibles coûts d’exploitation et minimise la quantité de l’eau utilisée pendant le cycle de nettoyage.

Des modèles avec réservoirs multiples: Des modèles de 1, 2 et 3 réservoirs et de plusieurs tailles sont disponibles.

Matériaux et conceptions conformes: Matériaux et finition conformes aux exigences 3A et ASME BPE. Joints compatibles FDA. Les exigences seront satisfaites selon la demande du client : ASME, UL, CRN Canada, CSA, CUL.

Nous tenons nos promesses: Nous ne ferons pas de promesses que nous ne pourrons pas tenir. Nous allons vous fournir le système dont vous avez besoin À TEMPS et À JUSTE PRIX

Des pièces de rechange: Haleson maintient un très grand inventaire de composantes sanitaires, telles que des pompes, des moteurs, des valves, des actuateurs, des joints, des raccords, des tri-clamps et des instruments. Nous vous assurerons que vous recevrez vos pièces de rechange dans des délais de livraison raisonnables, et ce, pendant plusieurs années à venir.

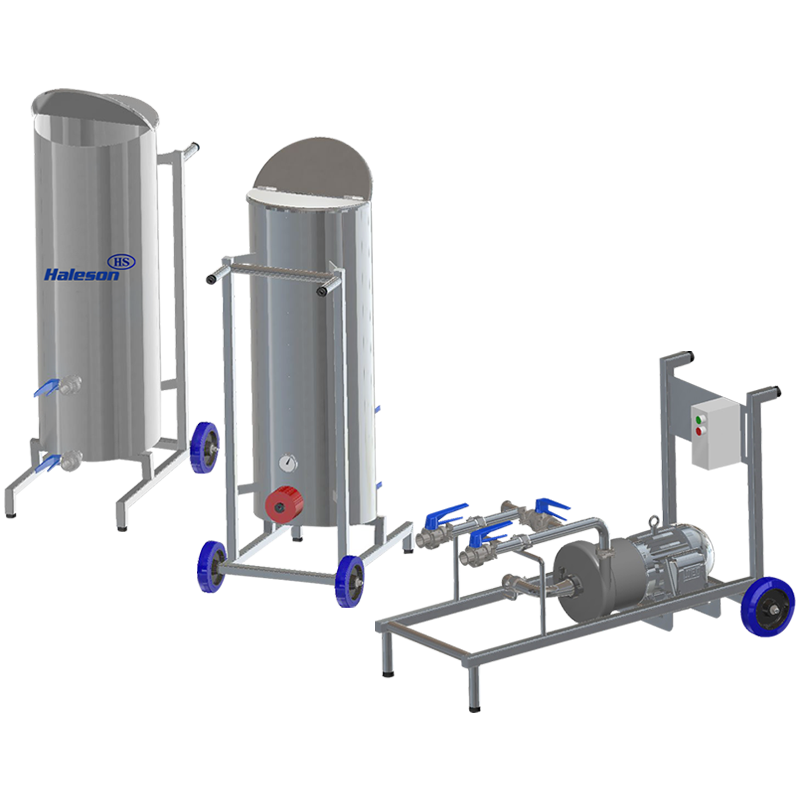

® Modèle Typique de système mobile CIP de 1000 litres (265 gallons US).

® Modèle Typique de système mobile CIP de 1000 litres (265 gallons US).Modèle prêt à l'emploi. Peut rapidement être déplacé partout dans votre usine, sur roues ou par élévateur à fourche. Design compact et léger. Très $ abordable..

® Modèles Typiques de système mobile CIP modulaire de 200 litres (55 gallons US) extensible à 400 litres (110 gallons US)

® Modèles Typiques de système mobile CIP modulaire de 200 litres (55 gallons US) extensible à 400 litres (110 gallons US)Pour plus d'informations sur le produit, s'il vous plaît voir le PDF: Systèmes NEP (CIP) Modulaires & Mobiles

Modèle prêt à l'emploi. Peut rapidement être déplacé partout dans votre usine, par une seule personne.

Très $ abordable. Design compact et léger.

La conception modulaire permet au système CIP d’accroître facilement sa capacité.

Unité de base de 200 litres (55 gallons) $US 16,500.00 ($CDN 21,000.00) environ. Options disponibles voir PDF.

Pour un 2e réservoir de 200 litres & chariot ajouter $US 7,500.00 ($CDN 9,500.00) environ.

Il n'y a pas de produits sous cette catégorie

Facebook

Facebook Instagram

Instagram